Will Your Heat Make It Through the Rest of Winter? A Mid-Season Reality Check for Philly Area Homeowners

We’re Halfway There… But Winter Isn’t Done With Us Yet

Look, if you’re reading this in mid-January, you already know. We’ve made it through the holidays, through those brutal cold snaps that hit right after New Year’s, and through at least a couple of those mornings where your breath fogs up inside your own house before the heat kicks in. But here’s the thing nobody wants to hear: we’ve still got two solid months of winter left, and February in the Philadelphia area? February doesn’t play.

Whether you’re in a Fishtown row home trying to keep your ductless mini splits running, out in Bensalem with a traditional system, or in one of those beautiful old Chestnut Hill houses with a boiler that’s older than your parents, right now is the moment to make sure your heating system can actually finish what it started

Because the absolute worst time to find out your heat is giving up is at 2 a.m. on a Tuesday when it’s 18 degrees outside and every HVAC company in the tristate area has a three-day wait list.

This isn’t about being paranoid. This is about being smart. Your heating system has been working overtime since November, and just like your car needs a check after a long road trip, your furnace, heat pump, or boiler needs attention before it decides it’s done for the season. The good news? Most heating failures give you warning signs, and there are real things you can check yourself right now that’ll tell you whether you’re good to go or whether it’s time to make that call before you’re forced to make that call.

Five Things to Check Right Now, Based on What’s Actually Heating Your Home

For Ductless Mini Split Heat Pumps (Common in Philly Row Homes, Northern Liberties, Fishtown, South Philly)

Your ductless system has been your hero if you live in one of those classic Philly row homes where adding ductwork would mean tearing down walls that have stood since before the Flyers existed. Here’s what to check:

Check your outdoor unit for ice buildup. It’s normal to see a little frost, but if your outdoor unit looks like it belongs in a freezer aisle, that’s a problem. Ductless systems go through defrost cycles, and if yours isn’t defrosting properly, it’s working way harder than it should. Clear away any snow that’s piled up around it (leave at least two feet of clearance), and watch to see if it goes through a defrost cycle where the fan stops and you might see some steam. If it’s encased in ice and never seems to melt, something’s wrong.

Listen to your indoor units. These wall-mounted units should run relatively quietly. If you’re hearing grinding, squealing, or rattling that wasn’t there in December, your fan motor or other internal components might be wearing out. Ductless systems are workhorses, but they’re not invincible, especially if they’ve been running nonstop through cold snaps.

Check your remote batteries and settings. This sounds almost too simple, but you’d be amazed how many service calls get made because someone’s remote died or got accidentally switched to fan-only mode. Make sure you’re actually in heat mode, your temperature is set where you think it is, and your remote is communicating with the unit (most units beep or flash when they receive a signal).

Look at your air filters. Most ductless units have filters you can pop out and clean yourself. If you haven’t touched them since installation, they’re probably clogged with dust, pet hair, and all the life that happens in a Philly home. Dirty filters make your system work harder, waste energy, and can eventually cause the unit to freeze up or overheat. Clean them with warm water, let them dry completely, and pop them back in.

Feel the air coming out. Put your hand under the indoor unit when it’s running. The air should feel warm to hot, not just slightly less cold than outside. If you’re getting lukewarm or cool air consistently, your system might be low on refrigerant, have a malfunctioning compressor, or be struggling in ways that need professional attention.

For Traditional Heat Pumps (Common in Northeast Philly, Bensalem, Levittown, Lower Bucks County)

If you’ve got a traditional heat pump with ductwork, you’re running a system that’s basically an air conditioner that learned to run backward. Here’s what needs your attention:

Inspect that outdoor unit. Just like with ductless systems, your outdoor heat pump unit shouldn’t be buried in snow or ice. Clear at least two feet around the entire unit. Check the top (the fan area) to make sure nothing’s blocking airflow. If you see ice caked on the coils that doesn’t melt during defrost cycles, or if the whole unit is sitting in a puddle of ice, you’ve got a drainage or defrost problem that needs fixing.

Check your emergency heat setting. Most heat pump thermostats have an “emergency heat” or “aux heat” setting. If your system has been running on emergency heat (you’ll usually see a light or indicator), that means your heat pump gave up and your expensive backup heat strips have been carrying the load. Emergency heat costs roughly twice as much to run and means your heat pump isn’t doing its job. If you didn’t manually switch to emergency heat and it’s running anyway, call someone.

Feel your supply vents. Walk around your house and put your hand over the vents where heat comes out. You should feel consistent, warm air from all of them. If some rooms are getting heat and others aren’t, or if the air feels barely warm, you might have ductwork problems, a failing compressor, or refrigerant issues. Heat pumps don’t blow air as hot as furnaces do (that’s normal), but it should still feel definitely warm.

Listen for the whoosh. When your heat pump cycles on, you should hear your indoor air handler kick on and air start moving through your ducts. If you hear the outdoor unit running but no air is moving inside, your blower motor might have an issue. If you hear clicking, banging, or grinding from either the indoor or outdoor unit, don’t ignore it.

Check your air filter. This is huge and almost everyone forgets it. Your filter (usually located near your air handler or at a return vent) should be changed every one to three months during heavy use. A clogged filter is the number one cause of heat pump breakdowns. It restricts airflow, makes your system overheat, and can cause expensive damage. If you can’t remember the last time you changed it, change it today.

For Furnaces (Common in Northeast Philly, Fox Chase, Bustleton, Horsham, Warminster)

Gas or oil furnaces are the old reliable for a lot of the area’s homes, especially the ones built in the ’50s through ’80s. Here’s what to check:

Look at your flame (if you can safely see it). If you have a gas furnace and you can see the burner flames through a viewing window, they should be blue with maybe a little yellow at the tips. If the flames are mostly yellow or orange, that indicates incomplete combustion and potential carbon monoxide issues. This isn’t something to mess with. Call immediately.

Check your filter, seriously. This is even more critical for furnaces than heat pumps. A dirty filter makes your furnace overheat, triggers safety shutoffs, and is the most common reason furnaces fail in the middle of winter. Check it right now. If it looks gray and clogged, replace it. If you can’t see light through it when you hold it up, replace it. Filters are cheap. New furnaces are not.

Listen for your blower motor. When your furnace fires up, you should hear the burners ignite (a whoosh sound), then after a short delay, the blower motor should kick on and push warm air through your house. If the burners fire but the blower never starts, or if the blower is making grinding or squealing noises, your motor or belt might be failing.

Check your thermostat batteries and settings. Dead thermostat batteries have caused more “broken furnaces” than actual broken furnaces. If your thermostat screen is dim or blank, replace the batteries. Also verify you’re in heat mode (not cool or off), your fan is set to auto (not on), and your temperature setting is actually higher than your current room temperature.

Look for rust, water, or soot around the furnace. Walk up to your furnace and really look at it. Any rust, water pooling, or black soot residue around the unit signals problems. Water means you might have a condensate drain issue or a cracked heat exchanger (serious). Soot means combustion problems (also serious). Rust can indicate age-related deterioration. None of these are DIY fixes.

For Boilers (Common in Older Philly Neighborhoods, Manayunk, Mt. Airy, Chestnut Hill, Historic Areas)

If you’ve got a boiler heating your radiators or baseboard heat, you’re running a system that’s probably been keeping Philly homes warm since before Rocky ran those steps. Here’s what needs checking:

Check your boiler pressure gauge. Most boilers have a pressure gauge on the front. It should typically read between 12 and 15 PSI when the system is cold, and up to 20-25 PSI when it’s hot and running. If your pressure is below 12 PSI when cold, your system might need water added. If it’s above 30 PSI, your pressure relief valve or expansion tank might have issues. Your boiler’s manual will have the exact specs, but wildly high or low pressure means something’s wrong.

Bleed your radiators if you have them. If you have old-school radiators and some rooms aren’t getting warm, you probably have air trapped in the system. You can bleed radiators yourself (there are tons of videos online showing how), but if you’ve never done it and you’re not comfortable, this is a quick service call. Trapped air makes your boiler work way harder and keeps rooms cold.

Listen for banging or kettling sounds. Boilers should run relatively quietly. If yours sounds like someone’s banging on pipes with a hammer, or if it’s making a sound like a tea kettle on steroids, you’ve got problems. Banging usually means steam is condensing in the wrong places or you have water hammer. Kettling (that high-pitched whistle or rumble) means sediment buildup or limescale is making water boil and steam inside the heat exchanger, which can crack it.

The kettling sound is especially important to catch early because it’s telling you sediment has been building up, possibly for years. When sediment sits at the bottom of your boiler’s heat exchanger, it acts like an insulator, making that section of metal get way hotter than it should. Water trapped under or around that sediment starts to boil and create steam bubbles that collapse violently, creating that rumbling or whistling noise. Left alone, this concentrated heat will eventually crack your heat exchanger, and at that point you’re looking at a full boiler replacement, not a cleaning.

Check for leaks or drips. Walk around your boiler, look at the pipes coming in and out, and check the floor underneath. Any water, any drips, any damp spots mean you have a leak. Boilers operate under pressure, and leaks only get worse. Small leaks waste water and energy. Big leaks can flood your basement and cause major damage.

Look at the flame (for gas boilers). Same as with furnaces, if you can safely see the burner flame, it should be mostly blue. Yellow or orange flames indicate a problem with combustion, which can mean carbon monoxide risks. If you smell gas at any point, leave your house immediately and call the gas company. Don’t mess around with this.

The Real Cost of Boiler Maintenance (And Why Waiting Makes It More Expensive)

Let’s talk straight about boiler maintenance costs because there’s a huge difference between what regular maintenance costs and what neglected maintenance ends up costing. A standard boiler maintenance visit in the Philadelphia area starts around $120 for a straightforward hot water boiler that’s been kept up reasonably well. That’s not expensive when you consider what you’re getting: a full inspection, cleaning, safety checks, and peace of mind that your heat will work when you need it.

But here’s where it gets complicated, and this is what a lot of homeowners don’t understand until they’re facing a much bigger bill.

Not all boilers are the same, and not all maintenance visits are the same. If you’ve got a steam boiler instead of a hot water boiler, that’s a different animal entirely with different components and different maintenance requirements. Steam systems are more complex, have more things that can go wrong, and take longer to service properly.

Then there’s the sediment issue. If your boiler hasn’t been maintained regularly, sediment and mineral deposits build up inside the heat exchanger and throughout the system. That sediment doesn’t just sit there harmlessly. It insulates the heat exchanger (making your boiler work harder and waste energy), it creates hot spots that can crack the exchanger, it clogs pipes and valves, and it causes that kettling noise that signals real damage is happening. Flushing out years of sediment buildup isn’t a quick job. It’s not a $120 job. It’s a several-hour process that might require special cleaning solutions, multiple flushes, and in severe cases, removing and cleaning components that can’t be flushed effectively while installed.

Some older Philadelphia homes, especially in neighborhoods like Chestnut Hill and Mt. Airy, have copper boilers or systems with components that require special kits or parts that aren’t standard anymore. Working on these systems takes more time, requires specialized knowledge, and the parts themselves cost more. A maintenance visit on a system like this isn’t going to be $120 because the work involved isn’t standard.

Here’s the pattern that happens over and over: someone pays $120 for basic maintenance when their boiler is relatively new or has been maintained regularly. Everything gets checked, cleaned lightly, tested, and they’re good for another year. Then they skip a year. Then another. Then five years go by. Now that same boiler needs sediment flushing, needs components that have corroded or seized up to be replaced, needs extensive cleaning, and might need that special kit to bring it back to proper operating condition. That maintenance visit isn’t $120 anymore. It might be $300, $500, or more depending on what’s been neglected.

The frustrating part is that all of that extra cost could have been prevented. If that homeowner had kept up with annual $120 maintenance visits, the sediment never would have built up to the point it needed aggressive flushing. The components wouldn’t have corroded from sitting in acidic, sediment-filled water. The system would have stayed efficient instead of working harder every year and racking up higher heating bills. But because they saved $120 a year for five years ($600 total), they’re now facing a $500 maintenance bill just to get back to baseline, plus all the wasted energy costs from running a dirty, inefficient system.

We work on a lot of boilers. Residential systems, commercial systems, church boilers that heat enormous old buildings with steam systems that have been running since the 1920s. The pattern is always the same: maintained systems cost less to maintain and last decades. Neglected systems cost progressively more to service, break down at the worst times, and fail years before they should. A boiler that could last 25-30 years with proper care might only make it 15 years if it’s neglected, and those last few years will be expensive and unreliable.

So when we say maintenance starts around $120, that’s real for a system that’s been maintained. If you’re calling for the first time in years, or if you’ve been hearing that kettling sound and ignoring it, or if you know your boiler hasn’t been flushed in forever, be prepared for an honest conversation about what your system actually needs. We’re not going to tell you everything’s fine when sediment is destroying your heat exchanger. We’re not going to do a surface cleaning and leave problems that’ll become your emergency next month. Real maintenance means actually maintaining the system, and if yours hasn’t been maintained in a long time, getting it back to a maintainable state costs more than keeping it maintained would have.

Red Alert Signs That Mean Call Right Now, Don’t Wait

The Sneaky Problems That Turn Into Big Bills (And How People Miss Them)

The frustrating thing about heating systems is that they rarely just die without warning. They give signs. They drop hints. They try to tell you something’s wrong. But most of us are busy, tired, and really hoping that weird noise will just go away on its own.

Dirty air filters are the silent system killers. This shows up on every list because it’s genuinely the most common problem and the easiest to prevent. A filter that costs four dollars, takes 30 seconds to replace, and gets ignored for six months can cause a $1,200 repair bill when it makes your system overheat and crack a heat exchanger or burn out a blower motor. The system has to work so much harder to pull air through a clogged filter that components wear out exponentially faster.

Ignoring small leaks turns them into big floods. That tiny drip under your boiler? That little puddle that shows up and then evaporates? That’s not fixing itself. Leaks in heating systems get worse, not better. A small leak might just waste water and energy now, but it’s telling you a seal is failing, a valve is corroded, or a pipe is cracking. Left alone, you’ll eventually come home to a flooded basement, water-damaged floors, and an emergency repair bill that’s five times what a preventive fix would have cost.

Weird noises that “aren’t that bad yet” are your system begging for help. That high-pitched squeal from your furnace blower? It’s a belt or bearing that’s about to fail. That grinding from your heat pump? It’s a motor on its last legs. That banging from your boiler? It’s sediment buildup or a pressure problem that will eventually crack something expensive. The thing about mechanical failures is they’re progressive. That noise that’s tolerable today will be unbearable next week and will be silence (because the system died) the week after. Catching it early when it’s just a worn belt or a dirty component saves you from catching it late when it’s a burnt-out motor or destroyed compressor.

Thermostat problems disguise themselves as system problems. You’d be shocked how many people call for a repair, pay for a service visit, and find out their thermostat batteries died or their settings got changed. Modern programmable and smart thermostats are amazing until they’re not, and a thermostat that’s not communicating properly can make a perfectly good heating system seem broken. Before you panic about your heat not working, verify your thermostat is actually calling for heat, has power, is set correctly, and is reading the temperature accurately.

Nobody checks their outdoor units until something’s obviously wrong. Your outdoor heat pump or ductless compressor sits outside in the weather doing all the actual work of heating your home, and most people never look at it from November to March. Snow piles up around it. Leaves and debris get sucked into it. Ice builds up. And then people are surprised when it stops working efficiently. A quick monthly check (is it clear, is it level, is it making normal sounds, is there ice that won’t melt) takes two minutes and can catch problems before they become emergencies.

Why a Simple Maintenance Visit Now Beats a $4,000 Emergency Call at 3 AM

Let’s talk about the actual math and reality of HVAC service calls, because there’s a huge difference between a planned maintenance visit and an emergency breakdown repair.

Maintenance happens on your schedule during business hours. You call on a Tuesday afternoon, you schedule for Thursday morning, a technician shows up when you’re ready, they do a thorough inspection, they catch small problems before they’re big problems, and they leave you with a system that’s cleaned, tuned, and ready to handle the rest of winter. You pay the standard service rate. You have time to plan if any repairs are needed. Nobody’s panicking.

Emergency calls happen at the worst possible times, and here’s what you need to know.

It’s 11 PM on a Sunday. It’s 3 AM on a Wednesday. It’s 6 AM on Thanksgiving. Your heat is completely dead, your house is getting colder by the hour, you have kids or elderly family or pets who need warmth, and you’re panicking.

Here’s the reality: most HVAC companies in the Philadelphia area don’t offer true 24-hour emergency service, and the ones that do charge emergency rates that are typically 1.5x to 3x normal service call fees. But there’s a smarter approach that can save you hundreds of dollars.

If your heat goes out overnight and it’s not a safety emergency, send a text message to your HVAC company. Many local Philadelphia contractors monitor text messages 24/7 even though they’re not dispatching trucks in the middle of the night. They’ll receive your message and can schedule you for first thing in the morning when their crews hit the road. You’ll pay normal service rates instead of emergency premiums, and honestly, the few hours you wait until morning will likely be about the same time you’d wait for an emergency tech anyway.

This approach is especially important for Philadelphia area homeowners who are budget-conscious. The reality is that your community isn’t looking to spend emergency rates if they can avoid it. If you can safely make it a few hours until morning (bundle up, use space heaters if you have them, close off unused rooms), you’re saving potentially hundreds of dollars. Emergency rates exist because you’re asking a technician to leave their family in the middle of the night, and that premium cost adds up fast.

The only time you need to call immediately for true emergency service is if there’s a safety situation: if you smell gas (that rotten egg smell), leave your house immediately and call the utility company and/or fire department. Same goes for visible flames, smoke, carbon monoxide alarms going off, or active flooding from your system. Those are genuine emergencies that need immediate attention from utility companies or emergency services, not situations where you wait.

For everything else (your heat stopped working but there’s no immediate danger), sending that text message and waiting for normal business hours means you get proper service at a fair price, and the technician who shows up is well-rested and can do thorough work instead of emergency triage at 3 AM.

What Actually Happens During a Professional Mid-Winter Heating Check

If you’ve never had a maintenance visit, you might be wondering what you’re actually paying for. Here’s what a legitimate HVAC company does during a heating system inspection:

For any heating system, they start with safety checks. This means testing carbon monoxide levels (for combustion systems), inspecting heat exchangers and combustion chambers for cracks or damage, verifying all safety switches and limit controls work properly, and checking venting systems to ensure combustion gases are leaving your house, not staying in it. These checks aren’t optional nice-to-haves. They’re life-safety items. Carbon monoxide kills people every winter.

They clean components that affect performance and longevity. Burners get cleaned. Blower wheels get cleaned (they collect dust like you wouldn’t believe, which reduces airflow and efficiency). Condensate drains get flushed. Coils get inspected and cleaned if needed. Air filters get replaced. These aren’t cosmetic improvements. Dirt and debris make systems work harder, use more energy, and wear out faster.

They test the actual operation and performance of your system. This means measuring temperature rise (for furnaces) or temperature differential (for heat pumps) to verify your system is producing the amount of heat it’s supposed to. They check refrigerant pressures and temperatures (for heat pumps and ductless systems) to ensure proper charge. They test startup sequences, run cycles, and shutdown procedures. They verify your system is cycling appropriately, not running too long or too short.

They check electrical components and connections. Loose electrical connections cause arcing, which causes heat, which causes failures and fires. Technicians tighten connections, test capacitors (which help motors start and run), verify amperage draws on motors, and check control boards. Electrical problems are progressive. A connection that’s getting loose will eventually cause a failure, and catching it during maintenance prevents that.

They inspect mechanical components for wear. Belts get checked for cracks and proper tension. Motors get checked for noise and bearing wear. Fan blades get inspected for cracks or imbalance. Moving parts get lubricated where appropriate. Mechanical components wear out with use, and catching wear before failure is the entire point of maintenance.

For boilers specifically, they assess sediment and scale buildup. This is where maintenance on a well-kept system versus a neglected system diverges significantly. A boiler that’s been maintained annually will have minimal sediment and might just need a light flush or none at all. A boiler that hasn’t been serviced in five years will have sediment that’s hardened and caked throughout the heat exchanger and possibly throughout the entire system. Removing that requires time, specialized cleaning solutions, multiple flushes, and in severe cases, might require removing and manually cleaning components. This is why maintenance costs can vary significantly for boilers. The technician isn’t trying to upsell you when they say your system needs extensive cleaning. They’re telling you the truth about what’s required to actually maintain your system and prevent damage.

They provide you with real information about your system’s condition and any recommended repairs. A good technician will tell you what they found, what’s normal wear versus what’s a problem, what needs attention now versus what to watch, and what things will likely need attention in the next year or two. This gives you the chance to plan and budget instead of being blindsided by an emergency repair. For older boilers especially, they’ll give you an honest assessment of remaining lifespan and whether continued maintenance makes sense or whether you’re approaching replacement territory.

The whole process typically takes 45 minutes to 90 minutes depending on system type and complexity (longer for boilers that need extensive cleaning or for steam systems which are more complex), and you walk away knowing your system has been checked by someone who actually knows what they’re looking at. For systems like boilers and furnaces that involve combustion and carbon monoxide risks, that professional inspection is genuinely important for safety. For all systems, it’s the difference between hoping your heat keeps working and actually knowing it will.

Trusted by Philadelphia’s Historic Churches and Houses of Worship

When you’re talking about boiler expertise in the Philadelphia area, there’s a reason R&R Mechanical gets called into churches throughout the region. Historic houses of worship, many with boiler systems that have been running since the early 1900s, require specialized knowledge that most HVAC companies simply don’t have. These aren’t your standard residential boilers. Church heating systems are often massive steam boilers or complex hot water systems that heat enormous buildings with high ceilings, multiple zones, and architectural considerations that don’t exist in typical homes.

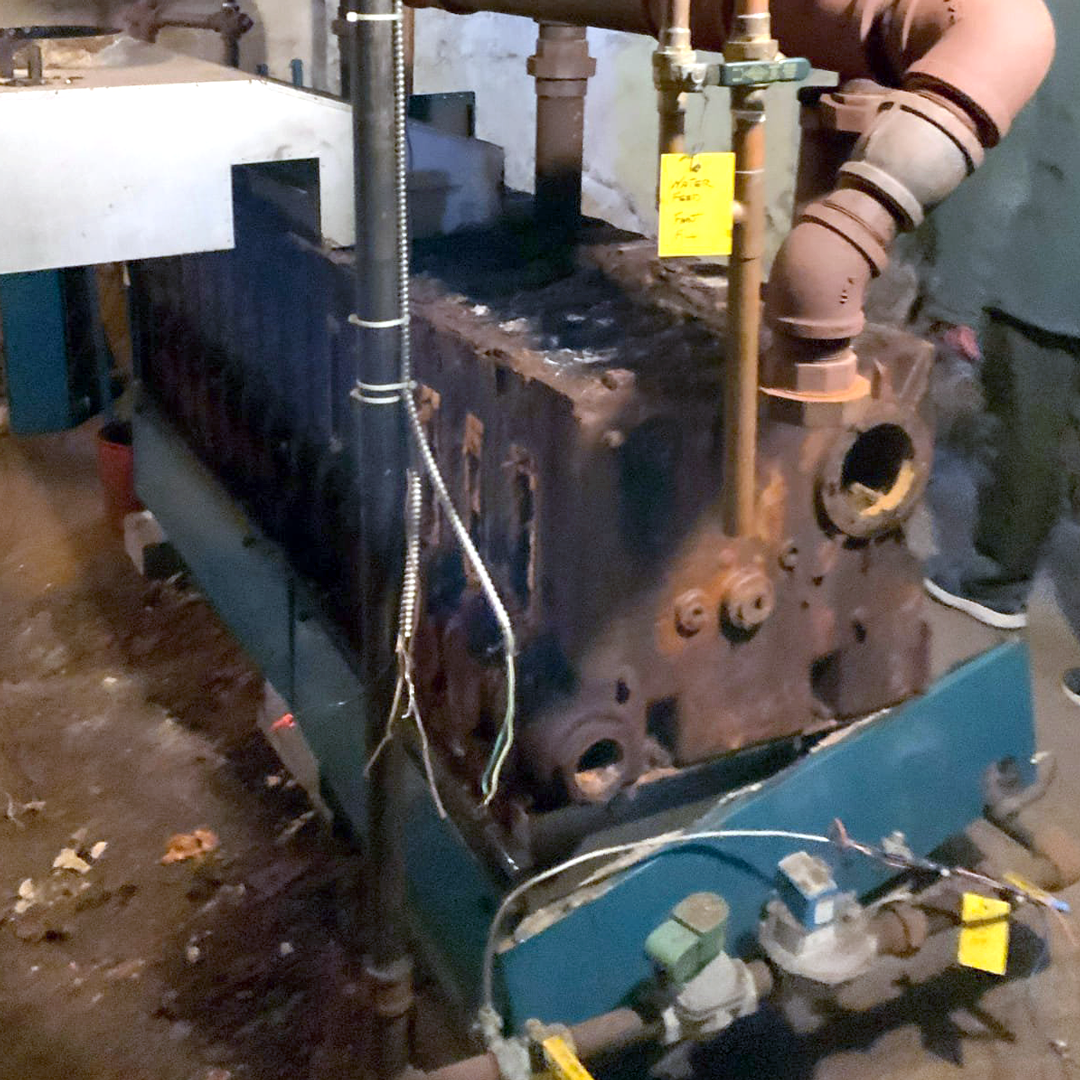

Remember that old, busted while rusted boiler at the beginning of this page? We will be updating the picture here with the newly installed boiler soon.

The fact that churches trust R&R Mechanical with these critical systems (because when a church boiler goes down in January, it affects services, community programs, and sometimes emergency shelter operations) speaks volumes about the level of expertise and reliability you’re getting. If R&R can keep a century-old church boiler running reliably through Philadelphia winters, they can absolutely handle whatever’s heating your Chestnut Hill row home or Bensalem ranch. That kind of specialized boiler knowledge, especially with steam systems and older equipment that many newer technicians have never even seen, is rare. When you call R&R for boiler service, you’re getting technicians who work on some of the most challenging heating systems in the region, not just cookie-cutter residential installs.